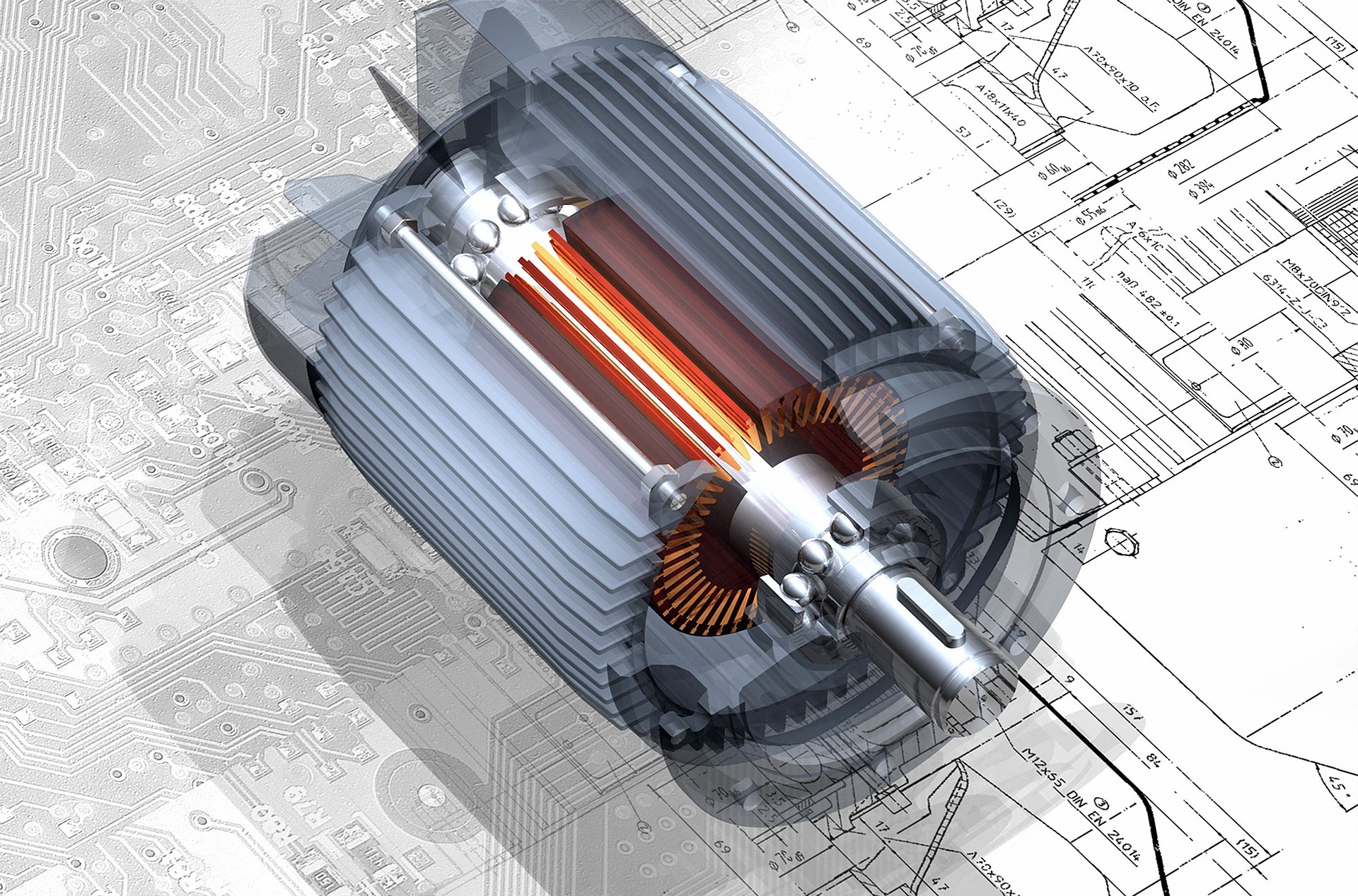

We recently had an opportunity to help an OEM/Supplier to stream line a process that is frequently forgotten but can have a significant impact on quality and productivity. That is the process of producing drawing notes.

Suppliers depend on the OEM that can change the applicable notes with evolution of standards. Either in 3D space using CATIA Functional Tolerancing & Annotations (FTA) workbench or in 2D drawing, problems may occur recurrently when a process that has the potential to be fully automated is neglected. When comes to methodologies based on start-up templates and interactive copy, paste and edit operations, we can be sure there is a lot of manpower behind.

Usually, technical notes involve not only text but frequent referral to other documents such as manufacturing standards with specific names and designations, multiple choices such as color, general detailed views dealing with specific techniques to apply and symbols such as datum, flag notes, tolerance boxes, roughness, welding and others. The cost of creating, modifying and therefore reviewing is high. Mistakes can cost at manufacturing.

To increase quality and productivity while mitigating the risks, the constant and meticulous task of checking can be considered as candidate for automation. Decisions are made upstream. Control too. Variable dimensions based on neat characteristics that are recognizable by a computer can drive the notes. Even notes from the reuse of existing parts are just as addressable by automation . Because nowadays, approximately written standard notes and small typos can be detected with practically human certainty and corrected by proven algorithms.

The experience was a success by ensuring more reliable notes, with less human errors or reworks and a significant reduction of design time.